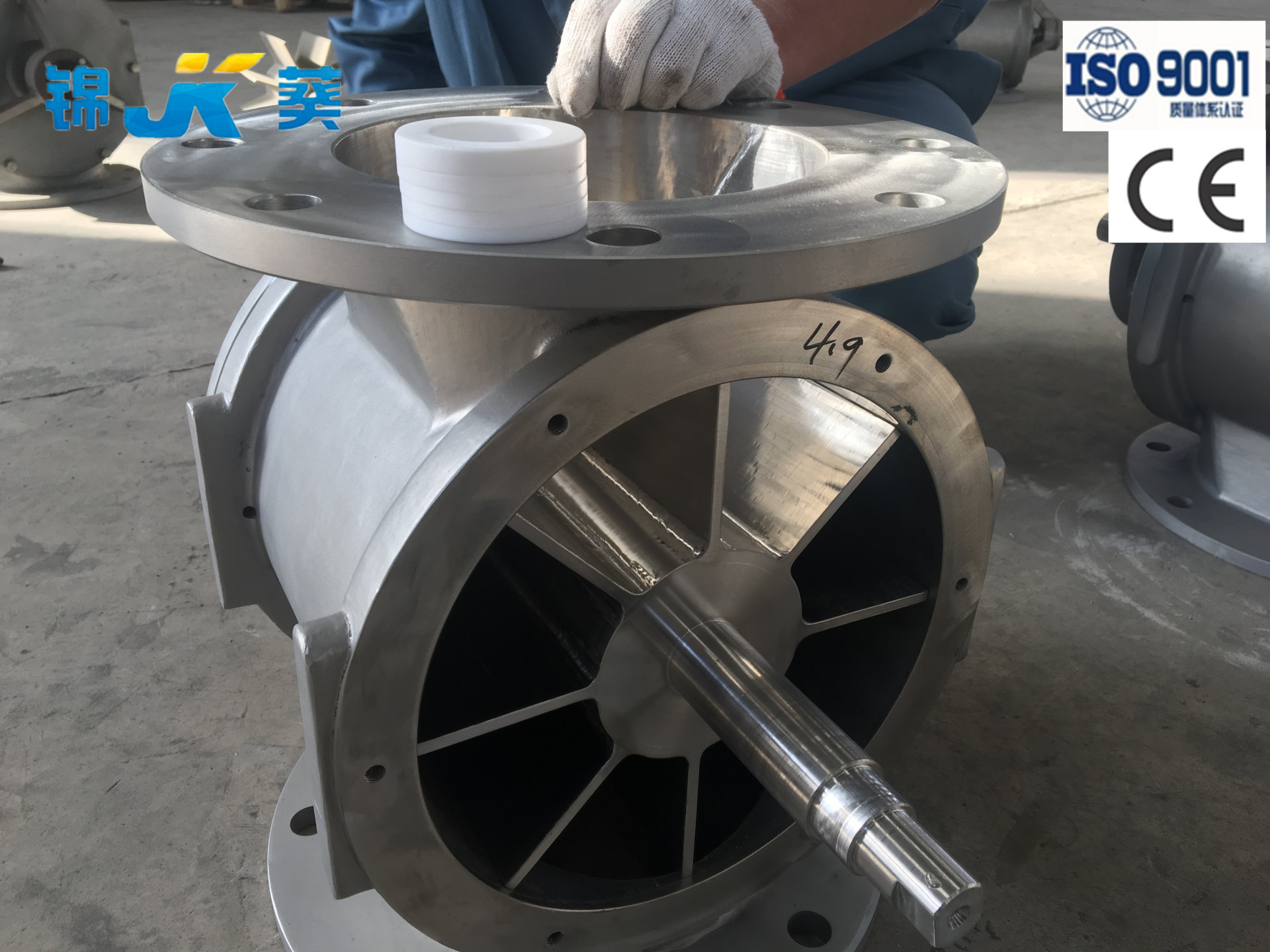

What are the debugging skills of the rotary valve?

Release time:

2024-10-22

Rotary valves are widely used. So, what debugging skills does it have? I believe that many of my friends don’t understand this very well. Let me briefly introduce it to you, let’s take a look!

Rotary valves are widely used. So, what debugging skills does it have? I believe that many of my friends don’t understand this very well. Let me briefly introduce it to you, let’s take a look!

Debugging method of rotary valve

1. Check the fastening of each part and whether the positioning pin is loose.

2. There is no oil leakage inside the rotary valve body.

3. There should be no scaling, rusting and peeling inside the rotary valve body.

4. Pay attention to whether the lubrication and heat dissipation are normal, pay attention to the quality of the lubricating oil, often listen to whether the rotary valve is noisy, pay attention to whether the unit is operating under conditions that do not meet the requirements, and pay attention to regularly adding butter.

5. The overload of the rotary valve is sometimes not displayed immediately, so pay attention to the increasing development trend of inlet and exhaust pressure, bearing temperature and motor current to judge whether the machine is operating normally.

6. Before disassembling the machine, measure the matching dimensions of various machines, make a record, and mark the rotation on the parts, and what debugging skills are there to ensure that the original matching requirements are maintained after the product is assembled.

Reasons for hydraulic clamping of rotary valve

Dirt enters the gap; the temperature rises, and the valve core expands, but the main reason is that the change of the side shape and coaxiality of the rotary valve causes the influence of the radial unbalanced force. When the valve core is affected by the radial unbalanced force effect and the valve hole When the liquid in the gap is squeezed out, the conflict between the valve core and the valve hole becomes a semi-dry conflict or even a dry conflict, and the force required to move the valve core from the head is much greater.

Changzhou Jinkuihua Machinery Manufacturing Co., Ltd. specializes in the production of rotary valves, air shutoffs, air shutoffs, star dischargers, unloading equipment, ash unloading valves, closed fans, dust removal equipment accessories, electric air locks, quick cleaning valves, deceleration Environmental protection equipment products such as machine, dust removal equipment accessories and so on. Customers in need are welcome to come to consult.

Hot information

Site navigation

Follow us

Mobile website

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Copyright © 2022 Changzhou Jinkui Machinery Manufacturing Co., Ltd.

powered by: www.300.cn | Tags IPV6