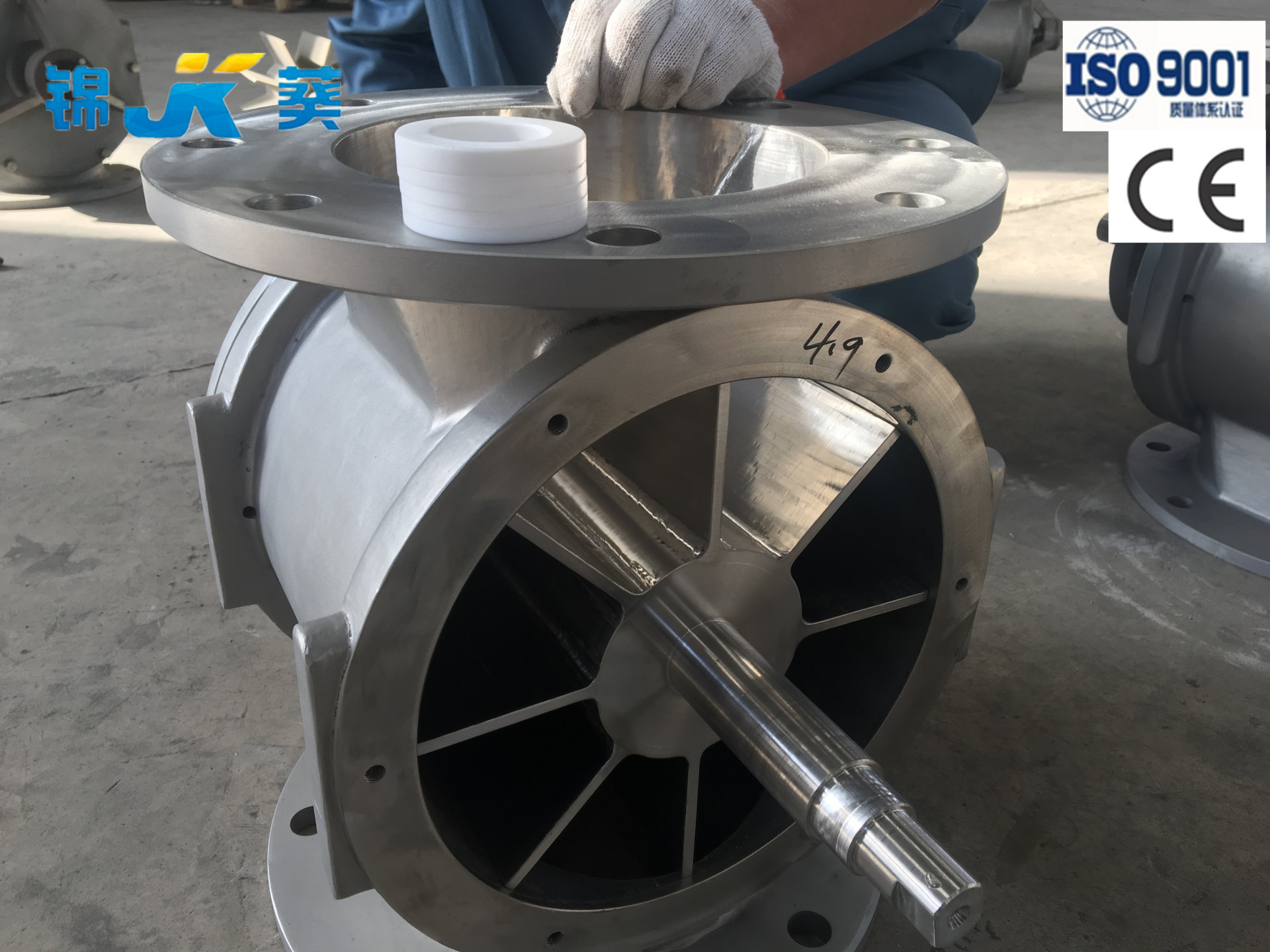

Five-layer seal_closed fan_closed fan

Changzhou Jinkui Machinery Manufacturing Co., Ltd. specializes in the production of rotary valves, blowers, blowers, star unloaders, unloading equipment, ash unloading valves, closed blowers, dust removal equipment accessories, unloader manufacturers, rotary valve manufacturers, metal Materials, quick cleaning valves, reducers, dust removal equipment accessories and other environmental protection equipment products;

key word:

Five-layer seal_closed fan_closed fan

Category:

Parts

Parts

Product description

Turn off the fan,It is usually used as the main equipment for dust removal equipment, air supply and other equipment feeding. Suitable for powder and granular materials. It is widely used in environmental protection, metallurgy, chemical, food, food and other industrial sectors. Let us understand common failures and improvement measures.

The common faults that Golden Sunflower recommends to turn off the fan are:

1. Turning off the fan is suitable for continuous work, allowing forward and reverse operation.

2. When the output shaft, input shaft and other parts of the discharger are accessories, direct, hammering and damage are not allowed.

3. During the transportation and installation of the fan, the fan should be stable to avoid collision and cause the shell to crack and deform.

4. During operation, avoid overloading operation of equipment due to large material particles and strong adhesion, or avoid equipment blockage or motor short circuit or equipment damage due to foreign matter and equipment in the dust collector. It is recommended that users check and install overload protection devices in time.

5. During use, if the equipment leaks air or dust along the axial direction, the gland can be firm.

6. Before the air shutter leaves the factory, the reducer has been filled with 00 lubricating oil, and the dust discharge valve has been filled with lithium base grease. Transmission and bearing parts should be refilled with grease or replaced with grease within 6-10 months after use. If the ambient temperature is high, humid or there is too much dust in the air, the oil change time should be shortened appropriately.

Improved knowledge of turning off the fan:

1. In order to prevent the ash at both ends of the impeller from entering the bearing due to severe bee leakage, the lower volume of the impeller end is increased with an ash discharge groove; to prevent poor lubrication of the bearing due to high temperature, the bearing box is replaced with an external bearing box.

2. In order to prevent foreign matter from falling into the silo and blocking the unloader impeller and burning the motor, please use a dry overload protection clutch instead of the safety pin in the previous product.

3. An inspection hole is installed on the side of the housing above the impeller.

4. There are two kinds of driving devices, gear difference planetary reducer and cycloid pinwheel reducer, which can be selected according to needs.

5. The impeller and the end cover, the dynamic and static connection parts adopt alloy wear-resistant sleeves.

6. The fan is usually not equipped with manual gate valve, which is convenient for maintenance, troubleshooting and replacement.

7. The impeller is equipped with rubber skin to prevent dust from squeezing into the bearing and blocking large particles.

Recommended products

Product quotation

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: +8613961297797